-

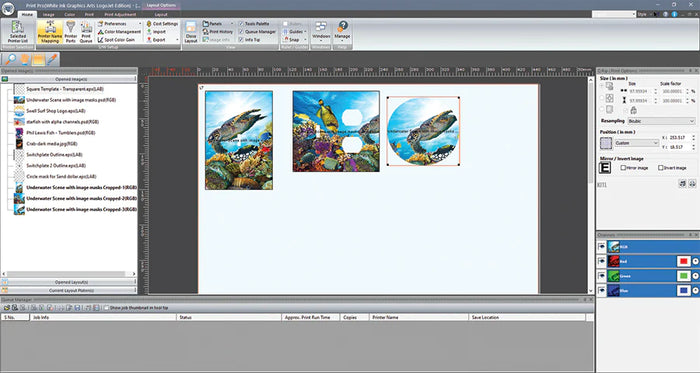

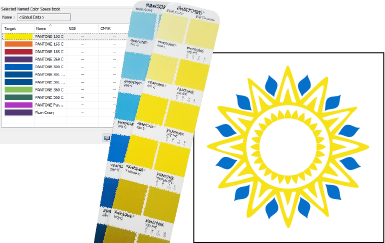

ENHANCED COLOR MANAGEMENT: COLOR INK OPTIMIZATION SYSTEM

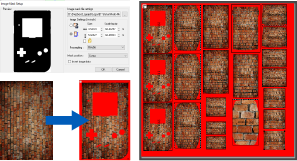

Color IOS is groundbreaking, patented technology that enables users to treat the background color of a substrate as an ink, thereby reducing the amount of white underbase required. As an available feature of Print ProTM, Color IOS can provide substantial ink savings as compared to current methods, without compromising the final color output.

-

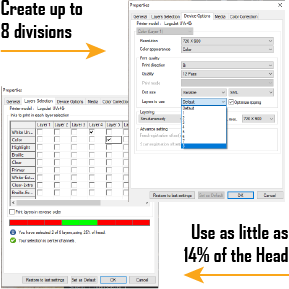

INDEPENDENT CHANNEL LAYERING

Independent channel layering allows any available channel to fire independently or in line with other channels. Combined with channel data from any popular art program, this opens up the possibilities for print operators to produce very advanced print techniques such as layering for textures and 3D effects.